Shipping from 7440 NW 52nd Street, Miami, FL 33166

Or welcome to contact us for shipping details(Transport by sea).

Parameters:

| Model | Power |

Capacity |

Engine | Packing Size |

Net/Gross Weight |

| PMFR8E40 |

30KW | 350-450kg/h | Electrical Engine | 1400*800*1450mm | 770/810kg |

| Pellet Size: Can Adjust By Your Demand | Warranty: 1 Year | ||||

Wood Pelletizer Machine Accessary & Packaging:

Payment Terms: L/C T/T

Package: Wood Case

Delivery Time: 20 Days

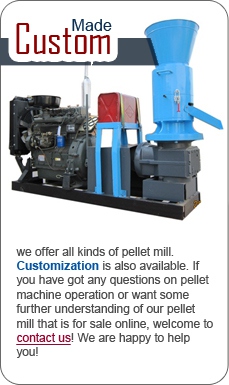

Pelletizer Machine Details:

Roller Parts: One of the most important parts of pelletizer machine is the roller. The rollers of all the pelletizers (pellet mill) we supplied are made from precise material of alloy metal and it makes the roller no easy to broken and anti-bearable. The simplest pelletizer machine has one pair of rollers. However, the new developed flat plate pellet press machine have two or three pair of rollers which have bigger capacity of making pellets (this kind of pelletizer have a higher price compared with traditional design).

Die Parts: The die parts have many holes for shapping the raw material into pellets. The diameter of the holes range from 6 to 8mm and you can shoose the right die depending on your needs.

Pellet Machine Spare parts details

Why do you use R-type wood pellet mill to process hardwood?

The R-type pellet mill has a rotating roller and a stationary die. The rotating roller can put a positive force to the hard raw material and resist counterforce, thus the hard wood sawdust can be better pressed with tighter density as 1.1*10³kg/m³.

When making hardwood pellets, it is strongly advised to add some proportion of softwood sawdust. This is not only good for your wood pellet maker, but also can produce better quality pellets with smooth and even shiny surface.

Features of PMFR8E40 R-type wood pellet mill

- The wood pellet mill machine box adopts carbon steel that has 350-500MPa strength of extension, which is twice that of casting structure (160-220MPa).

- It has higher dynamic, and the spindle torque is twice that of the same capacity D-type pellet mill, which makes it more suitable to process hardwood.

- The intensity of main shaft, roller shaft and bearing is twice that of die rotating pellet mill which also ensures its safety and reliability.

- The reduction gear adopts advanced gear transmission with extremely low noise.

- This R-type wood pellet mill adopts central adjusting interval between roller and die, which is more convenient and balanced.

Pellets Produced By The Pelletizer Machine:

5 Factors Influnces Your Pellet Quality

Moisture content

Moisture content is always important in the whole process of pellet production. Higher moisture content of the raw materials may result in higher moisture content in the final pellet moisture content. When the moisture content of the pellets extruded out of the pellets machines is higher than 15%, it will influence the pellet quality badly. Because the high moisture may rotten the pellets because of the decomposition of the batteries and fungus. When the final pellets moisture content is lower than 5 %, the pellet may easy be broken during fraction caused in transportation and storage.

Density

DurabilityThe durability of the pellets refers to the ability or the strength and resistance of the pellets to remain intact from being broken during transporting and storing. Usually, the moisture together with the water soluble compounds such as starch and lignin functions as a binding agent as well as a lubricant to increase the pellet durability by increasing the contact area between the particles.What’s more, the pellet durability also is also subjected to the particle size. The finer of the particles, the higher durability of the pellets is .

Fines percentage

The fines are produced by the broken pellets caused by frictions during transporting and storing. It is simple to understand that the less of the fines or dusts are, the better of the pellet quality is . The bad quality pellets intend to produce more fines which are endanger the burning equipment, by increasing the chance of dust explosion and other combustion problems. According to Shanke et al’s study, the storage temperature will affect the quality of the pellets and the higher storage temperature at around 30 to 50℃ will increase the fines percentage during two months storage time by more than 1 %.

Heating value

The heating value of the pellets are usually affected by processing variables, such as the die temperature of the pellets machines, particle size of the feed stocks, and the pretreatment of the feed stocks. Usually, the higher heating values come with higher pellet density. The general heating value of wood pellets are around 17 to 18 MJ/kg. However, the proper pretreatment can increase the heating value of the pellets to 20-22 MK/kg when the pellets are torrefied under the temperature of 200 to 300 ℃。

Pellet machine variables

Last but not least, the pellet density is also affected by the pellets machine variables, such as the dimensions and speeds of the dies of the pellet machines. Smaller pellets machine die dimension produce higher pellet durability. Die speeds of about 126 – 268 rpm are suitable for small pellet production while the die speeds of about 6- 7 m/s are always the choices for large sized feed pellet production, according to the study of the Stevens in 1987.

For more information, please visit this product's webpage.

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine