Shipping from 7440 NW 52nd Street, Miami, FL 33166

Or welcome to contact us for shipping details(Transport by sea).

| PDF of PMF8E10 Pellet Machine |

PDF of All Pellet Mill Machine |

Parameters:

| Model | Power ( hp ) |

Capacity ( lb/hr ) |

Engine | Packing Size ( in ) |

Net/Gross Weight ( lb ) |

| PMF8E10 | 10 | 176~265 | Electrical Engine | 41*19*37 | 441/507 |

| Pellet Size: Can Adjust By Your Demand | Warranty: 1 Year | ||||

Pellet Machine Details:

Die Parts: The die parts of this machine have many holes that are used for shapping the raw material into pellets. The diameter of the holes range from 6 to 8mm and you can shoose the right die depending on your needs.

Roller Parts: Rollers are the core parts of pellet machine. The rollers of our pellet machines are made of precise material of alloy metal which makes the roller anti-bearable and no easy to broken. The pellet machine has one pair of rollers. However, the new developed flat plate design pellet machine have two or three pair of rollers which have bigger capacity of making pellets.

This is a screw type pelletizer machine (gear driven), unlike belt driven pelletizer, the service life of this kind of machine is largely extended.

Pellet Machine Accessary & Packaging:

Payment Terms: L/C T/T

Package: Wood Case

Delivery Time: 20 Days

Biomass Pellets Produced By This Pellet Machine:

|||

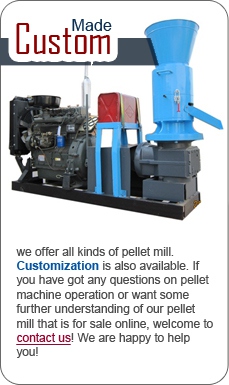

Top quality pellet mill for wood and fertilizer pellet machine from professional pellet machine suppliers. Low pellet machine cost,free after-sale service with money back guarantee.

Pellet Machine Supplier In USA

The number of pellet machine supplier manufactruring both residentinal pellet machine and industrial pellet machine around the world is growing. Although the pelleting principles is similar with the same core parts named die and roller, the pellet machine design and costs do differ. Different pellet machine may be produced for different purpose. Some suppliers offer pellet machine for pressing feed pellets, some offer pellet machine for making solid fuel and there are also fertilizer pellet machine. Flat die pellet machine is the oldest design of pellet making machine and we are the best western supplier manufacturing pellet machines with flat die. The core parts such as rollers, dies and bearings are made from high alloy steel, so you don't need to concern over excessive wear of pellet die and roller.

Choose flat die pellet machine for fertilizer or home pellet making can reduce both the production costs and spare parts costs. Moreover, heating treatment can increase the lifespan of flat dies while ring dies buckle under heat treatment and increase pelleting cost. Also it has be proved that pelleting low density raw materials with ring die is inappropriate.

How Can You Benefit From Pellet Machine?

There are reports that the demand for wood pellets are growing and this is meant, the need of pellet exceeds supply. Over the years to come, fuel pellets and fertilizer pellets will play important roles because of the growing business value and low cost and both large-scale and small-scale pellets suppliers can benefit from pellet machine.

To be a pellet supplier, first of all, you need to buy the right pellet machine. If you want to do fertilizer business, you need a fertilizer pellet machine, but if you are interested in fuel pellets, you should buy a wood pellet machine. As wood pellet machine has a higher profit, there are more and more suppliers claim that their pellet machine can produce wood pellets. So it is necessary for you to tell the differences between a wood pellet machine and other pellet machines. When pressing pellets, wood pellet machine generated a far higher compression than fertilizer pellet machine. Flat die design and ring die design are two main types of pellet machine for sale. Making wood pellets with fertilizer pellet machine will break the external and internal components. However, it is safe to buy from a wood pellet supplier to make fertilizer pellets. Here we offer you an easy way to test if a pellet machine can make wood pellets – ask for a wood pellet making video and test the quality of produced wood pellets. Of course, customer visit is the best way! If interested in our pellet machine, you are welcome to contact us for some information about our pellet machines in detail, pellet machine manufacturing photos and wood pellet making videos are available.

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine