|

Home >

Operation and Announcements

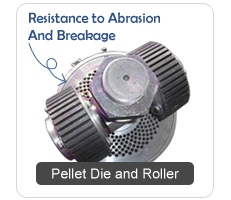

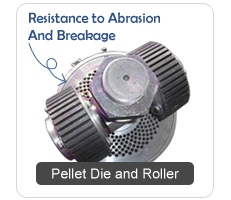

Operation and Announcements

Before operating a flat die pellet press, there is something you should know to make the press machine perform at its best and press high quality pellets. Below are the main instructions and tips for operating the pellet press machine.

- 1. Material Requirement: The moisture of material used for making pellets should be 14%-18%, the quality and quantity will be influenced if the moisture is higher or lower; the material to be fed into the pellet press must be well mixed.

- 2. Grinding-In of the New Flat Die: The new flat die should be grinding in as follows: 5kg material and 1kg sand should be well mixed with 1kg used oil. Start the pellet press and get the material in, then adjust the screw on the press roller, check whether the machine works well. (Please note: the space between press roller and die should not be too small, or the die and press roller will be damaged.) Fill in the normal material after the machine has been worked for 1 hour. If the pellet could not be molded after filling in the material, please loose the screw to the best result. If the pellet could not be molded after adjusting the screw, please empty the material in the nib with steel nail, (the top of the nail has been rub down), then start the machine for grinding-in. When the operators finish their daily work, they should fill in the oil material ( normal material with 10% oil) to the nib the prevent jam and to prepare for operating next time, as it will be time-saving.

- 3. Adjustment of The Space between the Die and Press Roller: The space between press roller and die affects the quality of pellets; the space should be 0.05-0.3mm. When the space is more than 0.3mm, the quantity of the production will be lower as the material is too thick. When the space is less than 0.05mm, the pellet mill will be damaged. The way to estimate of the press roller and die: it is better when we could not hear the noise when we fill in the material.

- 4. Choice of Length and Diameter of the Die Nib: When the nib is longer and diameter is shorter, the production quantity of the flat die pellet press is higher but hardness is lower, or the production quantity is lower and hardness is higher. So you can choose the right ones according to your requirements, or we can manufacture the suitable ones for you.

- 5. Adjustment of The Length of the Pellet: the height of the slicer which near the discharge hole could be adjusted then the length of pellet is adjusted.

- 6. How to Change the Die: Planishing the preiection between the stop washer and nut on the principal axis by screwdriver, get the nut with the hook head wrench (spare parts), get the stop washer and flat washer, then get the die with die opener (spare parts). The machine should be grinding-in again after changing the die.

- 7. Disposal Of The Finished Pellets: The temperature of the finished pellets will be higher so they should be placed in a cool place before packing.

American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)

Pellet Machine

(with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine

(Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ...

|

PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine