Shipping from 7440 NW 52nd Street, Miami, FL 33166

Or welcome to contact us for shipping details(Transport by sea).

| PDF of PMF12E30 Flat Die Pelletizer |

PDF of All Pellet Mill Machine |

Parameters:

| Model | Power ( hp ) |

Capacity ( lb/hr ) |

Engine | Packing Size ( in ) |

Net/Gross Weight ( lb ) |

| PMF12E30 | 29.5 | 662-1323 | Electrical Engine | 50*20*43 | 904/992 |

| Pellet Size: Can Adjust By Your Demand | Warranty: 1 Year | ||||

Pelletizer Machine Details:

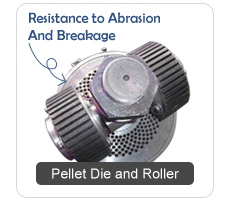

Roller Parts: One of the most important parts of pelletizer machine is the roller. The rollers of all the pelletizers (pellet mill) we supplied are made from precise material of alloy metal and it makes the roller no easy to broken and anti-bearable. The simplest pelletizer machine has one pair of rollers. However, the new developed flat plate pellet press machine have two or three pair of rollers which have bigger capacity of making pellets (this kind of pelletizer have a higher price compared with traditional design).

Die Parts: The die parts have many holes for shapping the raw material into pellets. The diameter of the holes range from 6 to 8mm and you can shoose the right die depending on your needs.

Wood Pelletizer Machine Accessary & Packaging:

Payment Terms: L/C T/T

Package: Wood Case

Delivery Time: 20 Days

Pellets Produced By This Pelletizer Machine:

|||

Best diesel pellet mills for sale.Certified pelletizer machine;Low pelletizer machine price. Buy from pelletmillshop, enjoy great after-sale service free!

Pelletizer Machine and Fuel Pelleting Process

The main objective of fuel pelleting is compress powdered organic materials into a larger, homogeneous mass by a pellet machine press or mill to make material handling easier. As a result, the transportation cost can be reduced and fuel value can be raised. Roller and die with a series of holes are the core part of a pelletizer, which means that the quality of roller and die largely affects the produced pellets. Pelletizer machines for sale on pelletmillshop.com can be used to pelletize various biomass materials, for both industrial pelleting and residential pelleting purposes.

Making pellets does not just mean find a pellet making machine at reasonable price among plenty of pelletizers for sale online. Suitable raw material and appropriate pelletzing knowledge is needed. This therefore means the correct moisture content and particle size.

Compared to straw and grass, woody material has a higher density. So wood pelletizer need some specific features such as sufficient power, a higher temperature and reasonable structural design and the price of pelletizer machine for wood is certainly a little bit higher. However, unlike grass or straw pelletizer machine for sale online, wood pelletizer operate at a lower speed in order to increase the time that pellet spends under compression in the die part.

How Cost-effective Fuel Pellets Are Made

Fuel pellets which are mainly produced from woody materials and agricultural wastes is the most popular market for pelletizer machines. When concerning woody materials, we are taking about both diseased woods, wood residues and purpose grown energy crop species like willow. Moreover, the demand growth of wood pellets is rapidly over these years due to its attractive price and high fuel value.

Though making pellets may seem very simple, many people are still wondering how fuel pellets such as wood pellets are produced. The main machinery used to make pellets are known as pellet mill, pellet press or maybe pelletizer. However pelletizing is kind of tricky and technically demanding process in fact. The reasons for this is that the characteristic and perform of various biomass materials are different during the pelletizing process. Knowledge and experience is required for a competent user to recognize how the material is performing and understand what is happening when the pelletizing dosen't go well. Accordingly, they can adjust the material or machinery. There could be a huge effect due to small adjusts to pelletizer machine. For instance, increasing the moisture content by 1% above the right percentage can make the energy consumption of pelletizer 30% higher. So if you don't want to waste you money, knowledge and experience is vital.

But you don't need to worry about that since we offer our customers a comprehensive pelletizer guide and free consultation service. If you have got any problems on pellet making process, welcome to contact us!

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine