Shipping from 7440 NW 52nd Street, Miami, FL 33166

Or welcome to contact us for shipping details(Transport by sea).

Parameters:

| Model | Power |

Capacity |

Engine | Packing Size |

Net/Gross Weight |

| PMFR12E30 |

22KW | 250-350kg/h | Electrical Engine | 1350*750*1400mm | 540/575kg |

| Pellet Size: Can Adjust By Your Demand | Warranty: 1 Year | ||||

Wood Pelletizer Machine Accessary & Packaging:

Payment Terms: L/C T/T

Package: Wood Case

Delivery Time: 20 Days

PMFR12E30 Pellet Mill Spare Details

PMFR12E30 pellet mill features:

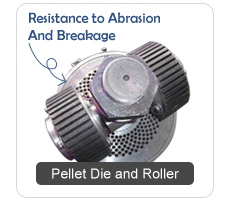

1. The main parts are durable to use. Main parts roller and flat die are made from high chrome alloy and processed by heat treatment, which is durable to use and wear-resistant. The gears are made from high quality alloy steel and processed by case-hardening, carburizing and grinding to have smooth transmission, low noise and long service life.

2. It can produce 6, 8, 10 and 12mm diameter high quality pellets. You can choose pellet size according to your need. The wood pellets made by this electric pellet mill have smooth surface, high density and not easy to break. So it is most suitable for people who produce wood pellets for sale.

3. There is sufficient supply of spare parts. If your electric pellet mill parts wear out, you can get them whenever you need from GEMCO.

Usually for people who want to set up large pellet plan for hard wood but not sure about the pellet market, they often purchase a ZLSP300B R-type electric pellet mill for trial order. And most of the time it performs satisfactory. If you are in similar situation, you can also buy this electric pellet mill first.

How does a pellet mill work?

Generally, take biomass pellet mill for example, there are three stages involved in the raw material densification. In the first stage, the particles rearrange themselves to form a closely packed mass but without changing their properties too much and the energy is dissipated due to inter-particle and particle-to-wall friction. In the middle stages, the particles are forced against each other and undergo plastic and elastic deformation, which increases significantly the inner-particle contact. In the last stage, the density of the fuel pellet increasing significantly due to the high pressure casted by the pellet mill. The processing of the particles are presented in the following diagram.

After going through, the three stages, the deformed and broken particles will not be able to change positions because of the decreased number of cavities and the conformity of the inter-particle. Well, it is also important to know that the densification process and the variables that govern its performance, such as the temperature, pressure, and equipment.

Pellets Produced By The Pelletizer Machine:

Four Considerations Before Buying a Pellet Mill

1. Quality comes first. Quality is the core of pellet production. At least, you need to choose a CE certified pellet mill.

2. Cost is one of the decisive factor . Ideal situation would be buying proper pellet mill from the manufacturers or suppliers with the lowest price. Here you should pay attention, the proper pellet mill does not mean the best one. Other words, you should choose a pellet mill after considering your budget, the capacity for large, medium and small scale pellet production, pellets application ( for business or self use, for feed or fuel, for boiler or stoves, etc,), power condition ( electricity, diesel, gasoline, etc) and serving life, etc.

3. Pellet mill operation and utilization affects the purchasing of the pellet mills. If the machine is too complicated to be operated, it may cause extra expense, such as cost for operator training and potential cost of machinery maintenance and operator securing which may be caused by wrong operation

.4. After sale service and spare part supply are also important for choosing a pellet mill manufacture and suppler. It’s better to choose pellet mills from a manufacturer or supplier who could provide satisfactory after sale service and consistent spare part supply, any of your problem can be solved at a phone call or an email.

Gemco Pellet Mills can bridging your needs from biomass to biofuel!

For more information, please visit this product's webpage.

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine