Parameters:

| Model |

Power

|

Capacity

|

Engine |

Packing Size

|

Net/Gross Weight

|

PMFR8E10

|

7.5KW |

80-120kg/h |

Electrical Engine |

950*450*1050mm |

215/245kg |

| Pellet Size: Can Adjust By Your Demand |

Warranty: 1 Year |

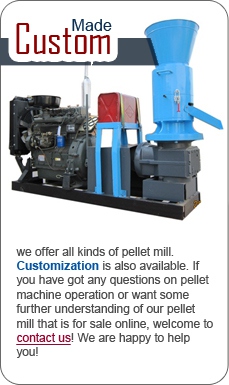

Pelletizer Machine Details:

Roller Parts: One of the most important parts of pelletizer machine is the roller. The rollers of all the pelletizers (pellet mill) we supplied are made from precise material of alloy metal and it makes the roller no easy to broken and anti-bearable. The simplest pelletizer machine has one pair of rollers. However, the new developed flat plate pellet press machine have two or three pair of rollers which have bigger capacity of making pellets (this kind of pelletizer have a higher price compared with traditional design).

Die Parts: The die parts have many holes for shapping the raw material into pellets. The diameter of the holes range from 6 to 8mm and you can shoose the right die depending on your needs.

Wood Pelletizer Machine Accessary & Packaging:

Payment Terms: L/C T/T

Package: Wood Case

Delivery Time: 20 Days

Pellets Produced By This Pelletizer Machine:

How does R-type Pellet Machine Work

Pelletizer Machine and Fuel Pelleting Process

The main objective of fuel pelleting is compress powdered organic materials into a larger, homogeneous mass by a pellet machine press or mill to make material handling easier. As a result, the transportation cost can be reduced and fuel value can be raised. Roller and die with a series of holes are the core part of a pelletizer, which means that the quality of roller and die largely affects the produced pellets. Pelletizer machines for sale on pelletmillshop.com can be used to pelletize various biomass materials, for both industrial pelleting and residential pelleting purposes.

Making pellets does not just mean find a pellet making machine at reasonable price among plenty of pelletizers for sale online. Suitable raw material and appropriate pelletzing knowledge is needed. This therefore means the correct moisture content and particle size.

Compared to straw and grass, woody material has a higher density. So wood pelletizer need some specific features such as sufficient power, a higher temperature and reasonable structural design and the price of pelletizer machine for wood is certainly a little bit higher. However, unlike grass or straw pelletizer machine for sale online, wood pelletizer operate at a lower speed in order to increase the time that pellet spends under compression in the die part.

Reasons for You to Choose GEMCO Pellet Mill

1.Equipped with newly spike wheel and ensuring the capacity

2.Increasing the eyelet quantity in disc from original 28 to 70

3.High efficiency of all the eyelets by using the roller with a cross wheel in our machine

4.Saving 1-2 workers by adopting automatic materials discharge set

5.Prolonging the shaft bearing life by installing the circulation lubrication system

6.Avoiding materials into body and lengthen bearing life by improving seal technology

This product was added to our catalog on Tuesday 13 January, 2015.

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine