|

Complete Wood Pellet Making ProcessWood Pellet Making Fundamentals

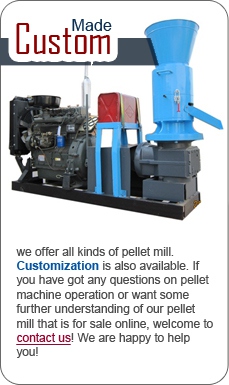

Initial Size Reduction: WoodWhen compress hard material with wood pellet maker machine, size reduction technology is an important consideration in the pelletizing because it can be the limiting factor of making good pellets as well as one of the most costly steps in the entire wood pellet making process. Not only does size reduction machine consumes large quantities of power, it determines, to a great extent, the operating, maintenance, and lifecycle costs of other machines in the a wood pellet line. For instance, if material is sized properly when it reaches the wood pellet maker machine, the die need only act as a forming device, not as a sizing device, which greatly enhances the die life and decreases energy consumption. Analogously, if material is less than 10 centimeters in diameter when it reaches the dryer, the resultant energy costs for the drying process than if it were greater than 10 centimeters as the smaller particles allow for the evaporation of moisture much more quickly. As a result, the typical wood pellet maker machine or pellet line that utilizes branches, logs, or other large-sized materials must engage in primary reduction before proceeding to other stages. Primary reduction is usually done with a disk chipper or a crusher. Chippers use replacement knives to split or shear whole logs or clean residue so that the geometry of the particles is relatively uniform and the structure of the wood remains intact. They are highly sensitive to contaminants, such as sand, rocks, and metal, which dull the blades. However, in the process of blowing the chips from the chipper to the next operational stage, most of the leaves and dirt are removed by the difference in particle density. The rotary speed may be as high as 3,600 rpm, which is two to three times faster than the rotary speed for the secondary piece of reduction equipment—the hammermill. For wood pellet maker machine and pellet line, the primary reduction should reduce the material to less than 10 centimeters. E-mail: info@pelletmillshop.com Our office staff is available to answer your questions, Monday through Friday, from 8:00 to 4pm (CST) American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF9E15 Biomass Wood Pellet Machine

PMF9E15 Biomass Wood Pellet Machine PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine