|

Wood Pellet Machine PlansFor wood pellet machine plans, the transportation of wood-based raw materials is relatively straightforward, tradeoffs exist in the delivery method for agricultural materials, of which there are three:

The first is the least intensive method, although is also the least effective for condensing the material. To create loose, chopped agricultural biomass it is only necessary to reduce the cut length of the forage chopper upon harvest. With a fine enough cut, this simple step may even eliminate the need for a wet hammermill in the wood pellet machine plans. Most choppers can process 30 to 100 dry tons per hour to a length as short as 7 millimeters. A self-propelled chopper can then discharge the materials into a separate truck or wagon. For temporary storage a simple bunker or plastic tube is sufficient until shipped to the wood pellet machine plans. Bales are more convenient for transportation since they can be stacked, although greater mechanization is required. Bales’ densities vary between 120 to 180 kilograms per cubic meter. For logistical purposes most bales are made to a width of 2.4 meters since this is the width of a semi-trailer truck. Bales of uniform size allow for more convenient stacking and handling by a loader. The straw is bound by twine or wire and, at a weight of 320 to 550 kilograms, requires mechanical loaders. Although round are cheaper to produce, for the production of biomass fuel it is recommended to make square bales. Square bales are more efficient to store and transport and are safer since they do not roll. Balers can process 10 to 20 tons per hour. A bale’s standard dimensions vary slightly by region, but the most common dimensions are: Straw, round: 1.5 meters in diameter by 1.2 meters; weight 240 kg. Harvesting agricultural products into cubes is distinct to Canada and is especially common in the feed industry. This process made the transportation of hay from the country’s remote west more convenient. The hay is first dehydrated, and then sent through a pressing wheel to produce the cubes which are about 4 centimeters in size. The cubes can be rapidly loaded with bulk handling material, are extremely durable and may themselves be used as industrial fuel. It is, however, rarely implemented for use in the international biomass fuel industry.

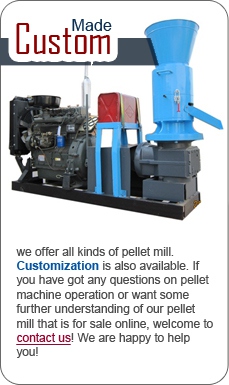

E-mail: info@pelletmillshop.com Our office staff is available to answer your questions, Monday through Friday, from 8:00 to 4pm (CST) American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine