|

Controlling Emissions From DryingTo make good pellet press plans and produce quality pellets, It is necessary to know about the details of every pellet production process. From initial size reduction, drying, initial sieving, grinding, pellet pressing, cooling, final sieving to storage. In this article we will focus on drying process of pellet press plans. Organic compounds are released by drying biomass materials as a result of volatilization, steam distillation and thermal destruction, which are thereby emitted into the air or wastewater. Organic emissions can be classified as volatile organic compounds and condensable compounds. In addition, there are particulate emissions that you should take into account when making pellet press plans. At low drying temperatures (under 100 degrees Celsius) the compounds emitted consist mainly of monoterpenes and sesquiterpenes. The volatile organic compounds are of environmental concern since they are known to form ground level ozone in the presence of nitrogen oxides.

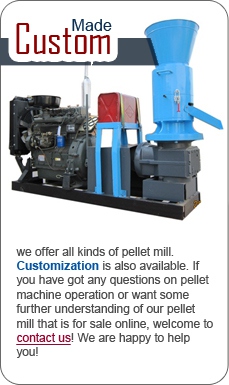

Photo-oxidants are also harmful to humans, as they cause irritation to the respiratory tract, particularly to the lungs. The condensable organic compounds, such as fatty acids, resin acids and higher terpenes, emitted at over 100 degrees Celsius, might condense on equipment surfaces and thus cause technical problems. They can also form “blue haze”, a discoloration of the exhaust plume, as the flue gases are cooled down after the chimney. The “blue haze” manifests itself as an odor and visual nuisance as well as a potential safety hazard. The thermal destruction of wood materials starts at about 150 degrees Celsius with the destruction of hemicelluloses, when alcohols, acids and aldehydes are released. In the initial stages of drying, thermal decomposition is slight, but the rate of loss accelerates rapidly as the temperature is increased further. Such degradation represents an energy loss to the overall process. The appropriate pollutant mitigating equipment for the exhaust gas stream depends on applicable emissions criteria and on local regulation, which varies greatly in different jurisdictions. Solid particulates may usually be dealt with via cyclones or bag filters. Blue haze is composed largely of sub-micron aerosols, and these are notoriously difficult to remove with conventional gas cleaning techniques. As a general rule low material temperatures (less than 100 degrees Celsius) should be maintained when possible. Want to know more about pellet press plans? Feel free to contact us! American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF9E15 Biomass Wood Pellet Machine

PMF9E15 Biomass Wood Pellet Machine PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine