|

How To Keep The Pellet Mill Function At Its PeakPellet mill machine which turn biomass wastes into green energy is known as a valuable fuel making machine. Pellet machine can compress a wide range of raw materials including wood wastes, animal wastes and agriculture wastes. One pellet mill cannot process all materials and you should buy the right mill depending on your specific raw material and requirements. Some people are looking for pellet mill to function with soft biomass material to produce animal feed pellets, and others are planning to buy a pellet mill to function with wood wastes to make fuel pellets. Whatever the pellet mill function, it will not perform efficiently unless the machine is maintained well.

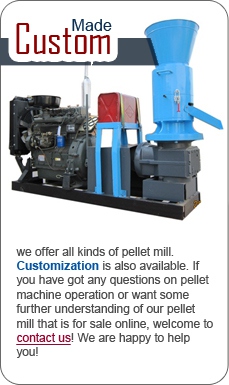

Actually the pellet mill functions are responsible for the pellet productivity and pellet quality. Even if you have got a brand new pellet mill and cost much money for the machine, bad pellet mill functions could also affect the pellet processing and as a result it only product substandard pellets. However if the mill machine is in good shape, they will produce high quality pellets easily. That is too say, there is something you should do to improve the pellet mill function and keep the it perform well. How To Improve The Pellet Mill Functions?There many ways to improve the pellet mill functions and adding lubricants is one common way. Referring to pellet spare parts, some parts have a reserve of oil while some transmission parts, gears for instance needs adding lubricant regularly as it runs. By this way, you can keep the pellet mill function at its peak and increase the output at the same time. Be careful not to spill to the compressing parts such as pellet rollers and dies when adding lubricant because this will lead to slip issues. Inspect the pellet mill on a regular basis is another way to improve the pellet machine function. Especially the easy-wear parts including pellet mill dies, rollers and bearings. As it is known to all, small mistakes can be a big mistake. A thorough inspection is really necessary so that you can find the faulty parts and correct it immediately before the machine break down. E-mail: info@pelletmillshop.com American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine