|

Home >

Making Pellets from Grass in 6 Steps

Making Pellets from Grass in 6 Steps

In US, pellet stove is becoming a common method of home heating. Compared with traditional wood-burning stove, pellet stove is more convenient and energy-efficient. You can buy fuel pellets at hardware stores or feed stores. With a small grass pellet mill, you can also make your own pellets from grass (lawn clippings), waste paper, peanut shells or other biomass wastes which might end up in a landfill. In this way, the costs for heating can be reduced. Does this Spark an idea? So start saving today!

Instructions

- Collect the lawn clippings after mowing. Lay the grasses on the ground in the sun and keep them in a thin layer and then pile them up.

- Start the grass pellet mill and preheat the mill for some minutes. In this process, the metal die inside the mill is heated so that the small amount of moisture in the grass can be dried during the pelletizing. Besides, with the heat, the natural lignin in the grass can be melted and become glue which helps hold the pellets together.

- Put a container such as a pail under the chute of the grass pellet mill. Feeding the dried grass into the hopper of the mill. Then the grass will be compressed into pellets and the finished grass pellets will fall into the container.

- Adjust the moisture content of the grass depending on the finished pellets. Crumbly pellets means the grass is too dry, so you need to mix the grass with some water. Mushy pellets means the grass is not dry enough, so you need to dry them longer in the sun. After a few tries, you can make perfect fuel pellets for your stove.

- Cool the pellets in the open air before storing. After the cooling, the pellets are ready for burning, so you can feed them into your pellet stove.

- Pack the unspent cooled grass pellets in bags and place them in a dry location.

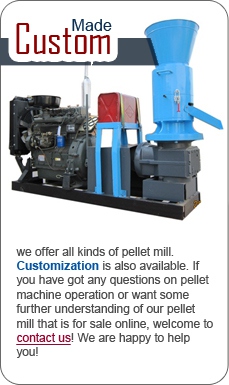

Small Grass Pellet Mill for Sale

Tips & Warnings

- Moisture content is crucial for the quality of the exited pellets. Good pellets are hard and shiny.

- There are many other raw materials suitable for making pellets except grass, such as cardboard, junk mail, crop waste or leaves.

- Before feeding into the pellet mill, the biomass must be crushed into small pieces, so a hammer mill or crusher is usually needed.

- The pelletizing process generates exhaust and dust so you are suggested to use the pellet mill outside the room.

- It is safe to wear eyewear and protective clothing during the pelletizing.

E-mail: info@pelletmillshop.com

Our office staff is available to answer your questions, Monday through Friday, from 8:00 to 4pm (CST)

American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)

Pellet Machine

(with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine

(Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ...

|

PMF9E15 Biomass Wood Pellet Machine

PMF9E15 Biomass Wood Pellet Machine PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine