|

Wood Pellet Maker Machine - DryingFlash Player is Needed

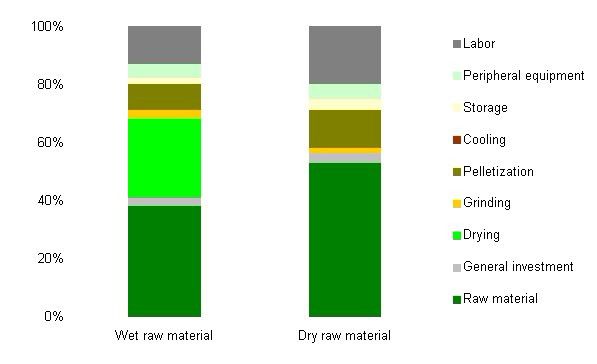

Table 6: Variable pellet making costs with wet and dry raw materials Dryer energy consumption is minimized by using an efficient thermal energy source, such as a biomass wood material, to dry the green material. In other words, the dryer need not be connected to the local electric grid to draw energy; existing biomass feedstock may be burned to produce the required heat. Using wood creates economies of scope associated with an wood pellet maker machine or wood pellet plant. Dust collected after the pelletizing process and during the bagging process can be recycled in the drying system. In an integrated biomass campus, waste products from other processes such as dried wood chips, sawdust, shavings, wood flour, wood waste could be used as dryer feedstock. Many manufacturers are capable of supplying wood pellet maker machines and dryers capable of firing with a variety of biomass sources, especially woody biomass. The moisture content of agricultural biomass, in contrast, is typically low. Straw delivered to the wood pallet maker machine or pellet production plant generally consists of air-dried bales, with a moisture content of between 15 and 20 percent. Compare this with wet sawdust which may register a moisture content of 50 to 60 percent. As the moisture content of straw and wood pellets after pelletizing is 7 to 12 percent, if straw material is used for pellet maker machine there is limited need for drying. Some agricultural biomass feedstock will require a more elaborate drying process, for example reed canary grass. With small-scale pellet production, costs are likely to dictate either batch perforated-floor technology using heated air, or a simple band conveyor using exhaust gas or heated air. It is only at mid-scale pellet production and above that a rotary dryer will come into play. If you are interested in pellet maker machine and large pellet plant, feel free to contact us! We are glad to help you. E-mail: info@pelletmillshop.com Our office staff is available to answer your questions, Monday through Friday, from 8:00 to 4pm (CST) American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF9E15 Biomass Wood Pellet Machine

PMF9E15 Biomass Wood Pellet Machine PMF9EC15 Biomass Wood Pellet Machine

PMF9EC15 Biomass Wood Pellet Machine PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine