|

Wood for Pelletizer EquipmentOne of the foremost considerations in deciding where to establish biomass pelletizer equipment is the availability of raw materials. In short, almost any sort of vegetation can be condensed into energy producing pellets although each has its own unique characteristics and behaviors in the pelletizer equipments. Wood for Pelletizer EquipmentWood and its derivatives are the raw materials most widely used for making pellets. Forestry operations often establish pelletizer equipment to make use of byproducts that might otherwise be discarded as waste. Debris from the harvesting of timber is collected for economic use. Cleared brush on tree farms is another source. However, the most common sources of material for the manufacture of wood pellets are the by-products of primary wood processing at sawmills and plywood plants: bark, sawdust, woodchips and shavings. Initial wood processing involves removal of the tree bark, which then becomes a by-product. Edging and trimming the lumber creates sawdust as the log is converted into boards. Whole slabs can be reduced into woodchips and mulch. Shavings are created as the lumber is then smoothed. These materials are superior for the pelletizing process in that fewer processing steps are necessary before entering the pelletizer equipments.

Flat Die Pelletizer Equipment

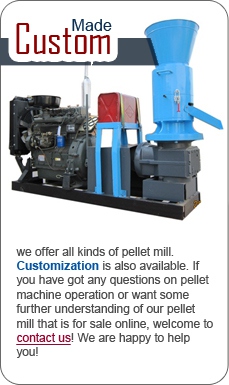

In locations without large-scale forestry operations the focus has been on the conversion of agricultural waste—notably straw—into biomass energy. This is due to its relative abundance and fast rate of rejuvenation. In Europe alone, it is estimated that an estimated 23 million dry tons is produced annually—double the weight of its current pellet demand. Denmark has been one of the leading countries in converting this agricultural product into energy. However, it is less often used than wood for several reasons. First, the material is characterized by low density. This creates problems in transport, as greater volumes of straw must be shipped and processed in order to match the calorific value of more dense materials such as wood. There are also higher traces of impurities in straw than in wood, such as potassium and sodium, which lead to slagging when burned. Specially designed boilers must be used to counter the effects of these impurities. Nonetheless, a number of agricultural residues are viable for making biomass pellets. American Biomass Pellet Mill for Sale (Wood/Sawdust/Straw......)Pellet Machine (with Diesel Engine)Here is diesel powered pellet machine extruder for sale! Pellet machine with diesel engine is a great alternative, especially for the area where three-phase electric power is not possible or quite expensive.With diesel engine, you can make... Pellet Machine(with Electric Engine)This series pellet making machines are powered by electric engine. With an electric engine you can precisely adjust the speed of the pellet machine die or roller by the transmission gear-boxes which is connected to the motor. By this way, you can con... Pellet Machine (Motor Has Been Covered)This series pellet fuel machines are powered by electric motor connected to a CE certificated electric cabinet. With the electric cabinet, the process of pellet maker became more intelligent and safe. If there is an emergency when you producing coal ... |

Copyright © 2011 Pellet Mill Shop. Powered by Altocraft USA.Inc

PMF6E6 Biomass Wood Pellet Machine

PMF6E6 Biomass Wood Pellet Machine PMF8E10 Biomass Wood Pellet Machine

PMF8E10 Biomass Wood Pellet Machine PMF10E20 Biomass Wood Pellet Machine

PMF10E20 Biomass Wood Pellet Machine PMF10EC20 Biomass Wood Pellet Machine

PMF10EC20 Biomass Wood Pellet Machine PMF12EC30 Biomass Wood Pellet Machine

PMF12EC30 Biomass Wood Pellet Machine